Amorphous Core with Notched Gap (Amorphous Ring-Cut Magnetic Core): 2026 Technology Landscape and Selection Guide

Jan, 04 2026

In the era of high-frequency and high-efficiency power electronics, the performance of magnetic components directly determines system efficacy. The Amorphous Core with Notched Gap, as a breakthrough technology, is driving transformation in fields such as new energy, 5G communications, and high-end industrial power supplies. This guide aims to systematically analyze the core principles, performance advantages, application scenarios, and selection logic of this technology, empowering engineers, designers, and procurement specialists to precisely grasp its application potential.

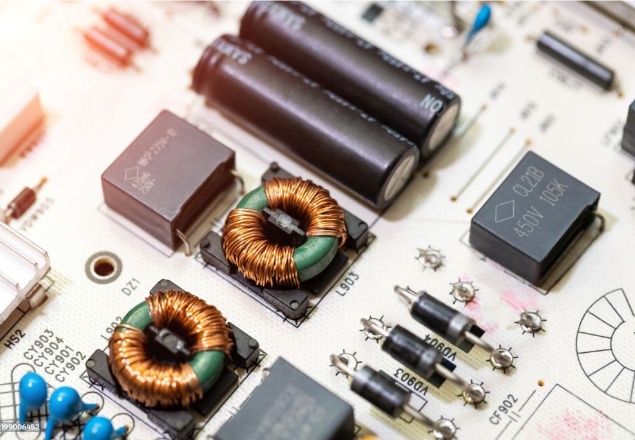

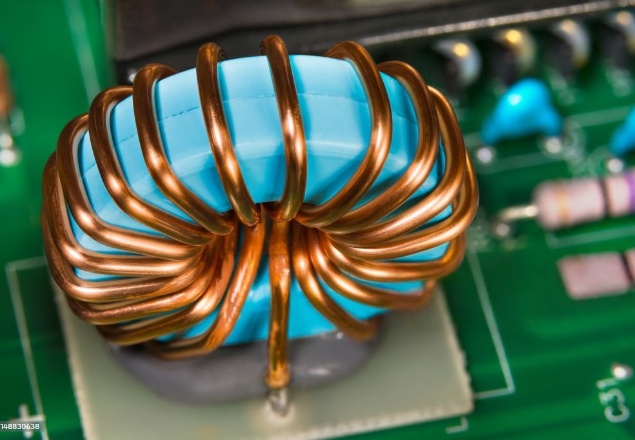

I. Amorphous Core with Notched Gap: Technical PrinciplesTo understand its excellence, an analysis from three dimensions is essential:"Amorphous" Material: Produced via rapid solidification (cooling rate > 10⁶ K/s), forming an amorphous alloy structure with disordered atomic arrangement. This structure eliminates grain boundaries and magnetic domain pinning sites, thus providing the fundamental characteristics of extremely low coercivity and high permeability.

"Toroidal" Structure: The closed-loop toroidal path provides optimal magnetic flux confinement, significantly reducing magnetic leakage, ensuring uniform magnetic field distribution, and enhancing energy transfer efficiency.

"Notched Gap" Design: A precisely machined specific notch or gap on the magnetic toroid. This critical design:Segments eddy current paths, effectively suppressing high-frequency eddy current losses.Relieves internal stress, enhancing thermal stability and mechanical reliability.Forms a distributed micro air gap, optimizing magnetic performance and heat dissipation.The combination of these three aspects makes it an ideal magnetic solution for addressing the challenges of high frequency and high power density.

II. Core Advantages: Why Choose Amorphous Cores with Notched Gap?Compared to traditional silicon steel, ferrites, and standard amorphous cores, its advantages are significant:Ultra-Low High-Frequency Losses: The notch physically interrupts large eddy currents. In frequency bands above 20kHz, eddy current losses can be reduced by 30%-50% compared to standard amorphous cores. For instance, under conditions of 100kHz and 0.5T, its typical total core loss can be as low as 250-280 kW/m³, directly improving system efficiency.

Excellent Thermal Stability and Heat Dissipation: The notch releases internal stress, combined with the controlled amorphous/nanocrystalline structure, resulting in minimal magnetic performance degradation (e.g., saturation flux density decay of only ~1.5%) after long-term operation at high temperatures like 150°C (e.g., 1000 hours). Simultaneously, the additional heat dissipation surface formed by the notch can reduce core temperature rise by 15-25°C.

High Permeability and Uniform Flux: High initial permeability (µi ≈ 5,000 – 6,000), coupled with optimized toroidal and notch design, results in extremely uniform magnetic flux distribution. This allows the core to operate at higher flux densities (increased by 15-20%), facilitating device miniaturization and higher power density.

Superior EMC Performance: The distributed air gap effectively suppresses magnetic leakage, potentially reducing radiated EMI by 5-8dB and conducted EMI by 3-6dB. Additionally, the notch disperses magnetostrictive vibrations, significantly reducing audible noise, meeting the demands of scenarios with stringent quietness requirements like consumer electronics and data centers.

High Customizability: Notch parameters (quantity, depth, distribution pattern) can be flexibly adjusted based on specific application requirements such as frequency (kHz to MHz), power level (kW to MW), and performance focus (e.g., loss, inductance, cost), achieving an optimal design balance.

III. Key Application ScenariosIts performance advantages are fully utilized in the following fields:High-Frequency Power Converters: Such as LLC resonant converters, phase-shifted full-bridge power supplies, used in server power supplies, communication base station power supplies, etc., to improve efficiency and power density.

New Energy Systems: High-frequency boost inductors in photovoltaic inverters, filtering and energy storage inductors in Power Conversion Systems (PCS) for energy storage, wind power converters.

Industrial Power Supplies & Motor Drives: Inductors and transformers in medium-to-high power switch-mode power supplies, UPS, variable frequency drives (VFDs), and servo drives.

Communications & Data Centers: 5G RF power supplies, Power over Ethernet (PoE) modules, 48V Bus Converters (BCM) in data centers.

Specialty Power Supplies & Medical Equipment: Power supplies for aviation, medical imaging equipment, etc., which have extremely high requirements for efficiency, temperature rise, and reliability.

IV. Key Considerations for SelectionWhen selecting an Amorphous Core with Notched Gap, a systematic evaluation is recommended:

Operating Frequency & Losses: Define the system's operating frequency band and compare the specific core loss (Pcv) curves of target cores within that band.

Power & Flux Density: Calculate the required flux density (ΔB) based on power level and topology, ensuring it remains below the core's saturation flux density (Bs) with sufficient margin.

Thermal Management Requirements: Assess system cooling conditions and select cores considering their temperature rise data and heat dissipation characteristics.

Size & Shape Constraints: Determine the core's outer diameter, inner diameter, height, and potential customized notch layout based on installation space.

Cost & Supply Chain: While meeting performance requirements, comprehensively consider initial cost, lifecycle cost savings from energy efficiency, as well as supplier stability and technical support capability.

Future OutlookAs power electronics evolve towards higher frequency, greater efficiency, and higher integration, Amorphous Cores with Notched Gap, leveraging their combined material and structural advantages, will continue to expand application boundaries. Coupled with advanced packaging technologies and intelligent design tools, they will become a key cornerstone in building the next generation of green, high-density power systems.