Amorphous Inductor: The "Invisible Heart" Behind the Energy Efficiency Revolution

Dec, 09 2025

Within the surging currents of new energy vehicles, amidst the leaping electromagnetic waves of 5G base stations, and during the silent energy conversion in photovoltaic fields, an "invisible heart" beats powerfully, reshaping the efficiency logic of the entire electronic world—this is the amorphous inductor. This mysterious component, with "metallic glass" at its core, is becoming a key force driving the green energy revolution and digital future through its groundbreaking material properties.

I. Unveiling "Metallic Glass": Why is the Amorphous Inductor Different?Amorphous alloy is a metal "frozen" into shape by ultra-rapid cooling at millions of degrees per second, its atoms arranged as disorderly as glass. It is precisely this unconventional structure that endows amorphous inductors with four extraordinary characteristics:

Superb Magnetic Conductance (Permeability up to 100,000-level): Like paving a "highway" for magnetic fields, it significantly enhances high-frequency filtering and energy conversion efficiency.

Extremely Low Loss (Core Loss Reduced by Over 40%): Minimizes energy waste as heat from the source, remaining cool and composed even during high-frequency operation.

Remarkable Stability (Operates from -40°C to 125°C): Unfazed by extreme cold or heat, with a service life potentially exceeding three times that of traditional inductors.

High Saturation Flux Density (>1.5 T) and Miniaturization: Carries greater energy within a smaller volume, perfectly meeting high-density integration needs.

II. Empowering Diverse Industries: From "Green Engine" to "Signal Guardian"

1. The "Efficiency Multiplier" for the New Energy Revolution

Electric Vehicles: On-Board Chargers (OBC) equipped with amorphous cores achieve up to 96% efficiency, reducing charging time by 20%; drive motor core loss plummets by 60%, while power density increases by 35%. Dozens of amorphous inductors are needed in each high-end electric vehicle. With China's annual production exceeding 6.88 million units, demand is growing exponentially.

Photovoltaics & Wind Power: Attenuates harmonics by over 80 dB in inverters, boosting system efficiency by 2-3%. Its micro-strain sensing capability can provide up to 30 days of early warning for micro-cracks in wind turbine gearboxes, safeguarding clean energy assets.

2. The "Signal Guardian" for High-Frequency Communication

5G Base Stations: Circulators based on amorphous/nanocrystalline cores achieve an insertion loss of only 0.2 dB and isolation up to 45 dB, serving as the unsung hero supporting Massive MIMO antenna performance.

Satellite Communication: Controls insertion loss to <0.5 dB in Ka-band equipment, enhancing deep-space signal transmission stability by 50%.

3. The "Precision Energy-Saving Officer" for Smart LivingFrom the precise control of industrial servo drives to the quiet efficiency of smart home power supplies, amorphous inductors enhance performance while propelling devices toward a future that is more compact and energy-efficient.

III. Market Landscape: Competition and Future in a Billion-Dollar Blue Ocean

Dimension

Status & Trends

Market Scale

Core component market reached 4.5 billion CNY in 2023 (+18%), projected to exceed 7 billion CNY by 2025 and surpass 10 billion CNY by 2028.

Industrial Layout

East China (58%): Center for scaled manufacturing; Northeast China (22%): Hub for high-end materials and device R&D.

Core Challenges

Production equipment for ultra-thin strips (<20μm) is limited; material costs need optimization; market is led by giants like Baowu and CITIC Pacific.

Growth Engine

New energy vehicle demand is projected to constitute 45% of total demand by 2025, representing the absolute core driving force.

IV. Practical Selection Guide: How to Effectively Utilize This "Invisible Heart"?

Faced with diverse needs, precise selection is key:

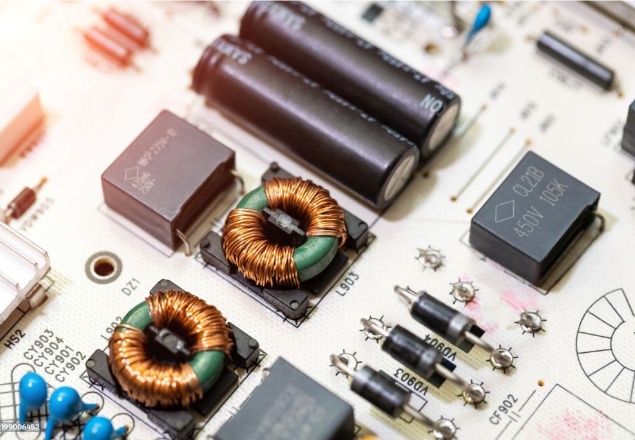

Selection by Structure:

Toroidal Core: Low magnetic leakage, high strength. The preferred choice for high-current filtering and scenarios with stringent EMC requirements.

Rectangular Core: Good heat dissipation, easy winding. Suitable for high-power inductors and transformers.

Cut Core: Adjustable air gap. Beneficial for small-batch customization and precise tuning.

Three Principles to Avoid Pitfalls:

Don't Blindly Worship High Permeability: Be wary of its sensitivity to DC bias; a comprehensive evaluation is necessary.

Strictly Assess Environmental Suitability: Especially in extreme environments like automotive and outdoor communications, temperature drift characteristics determine lifespan.

Consider Full-Spectrum Harmonics: Selection must cover the full operating frequency spectrum, not just the fundamental frequency.

Conclusion: A Small Component, A Vast Future

The rise of the amorphous inductor represents a fundamental materials revolution starting from the atomic structure. It is no longer just a component in electronic circuits but a strategic pivot empowering countless industries towards efficient, low-carbon transformation. For the industry, grasping its technological trajectory means securing a performance advantage for next-generation products. For society at large, understanding this "invisible heart" allows for deeper insight into how technology is quietly shaping a more efficient and greener sustainable future.